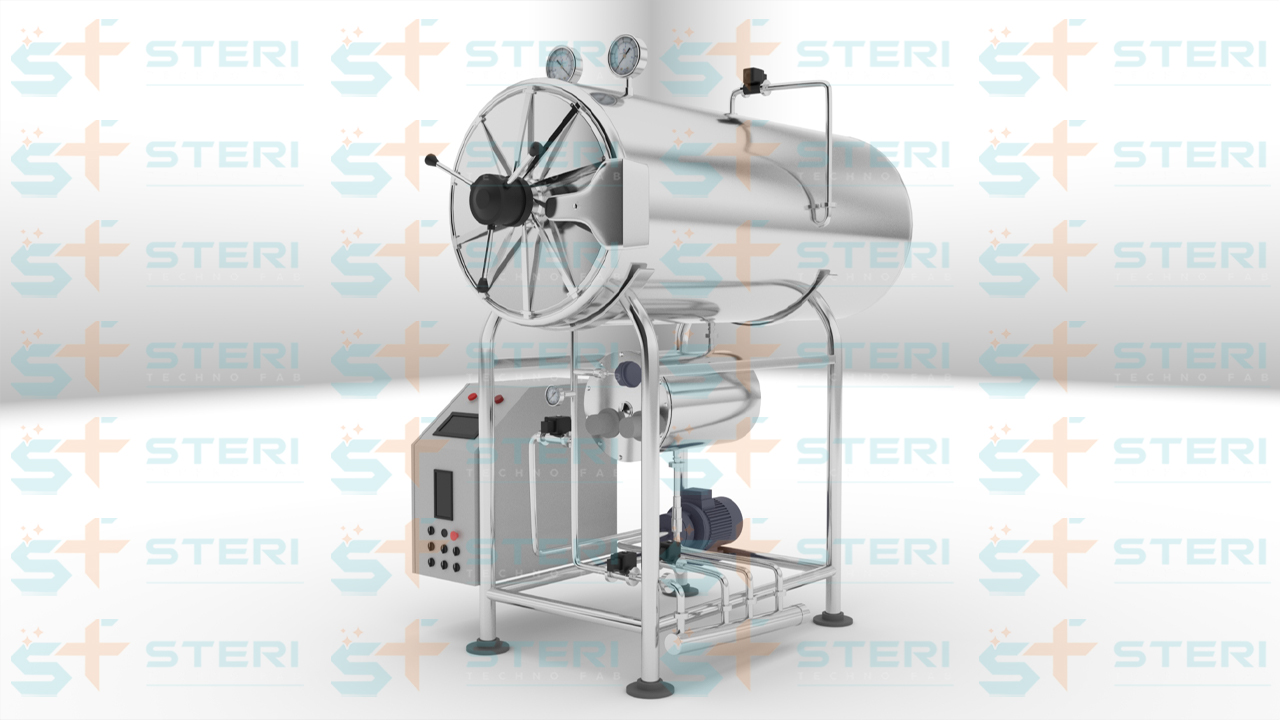

We are prominent name as the Horizontal Cylindrical Autoclave manufacturer and supplier, our horizontal cylindrical autoclaves are ideal for various industries. By offering a high quality Horizontal Autoclave, we have established a distinct position in the market. Our cylindrical autoclaves are thoroughly inspected to assure their quality before customer delivery. Furthermore, these high-speed sterilizers are designed in our state-of-the-art manufacturing facility by our trained specialists using the highest quality basic materials and cutting-edge technology. These high-speed sterilizers are available to our customers at very reasonable pricing.

Description

Horizontal Cylindrical Autoclave Manufacturer

Steri Techno Fab’s Horizontal Cylindrical Autoclaves are ideal for the healthcare and pharmaceutical industries, where huge volumes of sterilization are required. Our high-pressure horizontal cylindrical autoclave sterilizers are designed for academic institutions, biotech companies, pharmaceutical companies, hospitals, research centers, and the food and beverage industries. These equipments are particularly suited for sterilizing hospital dressings and surgical tools, rubber and plastic goods, glassware and cutlery, and other items that require thorough sterilization.

Product Details-

The sterilizer works on the basis that saturated steam at high temperatures has a rapid and thorough bacterial activity. All models work on the idea of downward air displacement, which is the most cost-effective form of sterilizing.

Construction– Triple walled steam jacket, with leak-proof argon welding, the inner chamber and steam jacket are composed of stainless steel. Lid S.S. is used to make this item. Ground levelling flanges are screwed to the autoclave, which is fixed on a tubular steel frame.

Pressure Control– All electrically operated sterilizers include a pressure control device. It saves energy by reducing the number of times the steam release valve is opened and preventing steam from entering the room.

Operating Pressure & Temperature

- 120° C sterilizing temperature

- 1.2 to 1.5 Kg/cm2 sterilizing pressure (15 psi-20 psi)

- Power: Suitable for use with a 440V, 3 phase, 50 Hz AC supply.

Salient Features of Horizontal Cylindrical Autoclave–

- The use of a vacuum system to remove air from within the chamber ensures that no air pockets obstruct the steam penetration and hence the sterilizing process.

- Standard 121°C & 134°C cycles that are pre-programmed in the memory of the PLC / Microprocessor are used to sterilize a variety of hospital equipment such as gloves, linen, gauze, cotton, tools, glassware, and so on.

- For all models with a chamber volume of 1000 liters or less, an electrical steam generator is included.

- The temperature must be kept constant and exact throughout the chamber, within 0.5°C of the Set Sterilization temperature.

- Internal air-pressure stabilization from vacuum using a 0.01-micron clean air-filter.

- When the chamber is under pressure, the door automatically locks. To ensure sterile chain integrity, both doors on double door models will not open at the same time.

- Safety valves for the jacket and chamber are included.

- The chamber is made of SS 304/S316 grade steel. The chamber is encircled and strengthened by a thick steel jacket.

- All machines can be ordered with traditional hinged doors or with Modern Automatic sliding doors.

- The chamber’s homogeneous and speedy pre-heating is ensured by the double-wall design.

- On request, a flush-mounted panel can be installed on the sterile side to ensure separation from the unmonitored operating environment.

Specification of Horizontal Cylindrical Autoclave

- The SS 304 grade SS is used to built our high pressure Horizontal Cylindrical Autoclave

- The horizontal autoclave is built to last and is ideal for all types of bulk sterilization jobs in the medical, agricultural, and pharmaceutical industries.

- Hospital dressing linen, rubber, plastic goods, surgical tools, glass wire, and other items can be sterilized in a horizontal cylindrical autoclave.

- The chamber’s homogeneous and speedy pre-heating is ensured by the double-wall design.

- The Horizontal Cylindrical Autoclave is triple walled, has a steam jacket, and is installed on a tubular stainless steel frame with ground levelling bolted flanges. To reduce heat loss, the outer jacket is lined with mineral wool. Hydraulically, these sterilizers have been tested to withstand 2.5 times the working pressure.

- The steam generator is built of heavy gauge stainless steel sheet and is fixed in front of the boiler on a heavy ring with folding thick stainless steel plate. It is equipped with a heating element and a low water level cut-off system to prevent the former from burning out.

- With the help of a “Multiport Valve” mounted on the front top, the entire sterilization cycle may be controlled from a single location. On gauges installed on the multiport valve, the jacket and chamber pressures are easily legible.

- The sterilizer is equipped with three levels of safety.

- At the boiler level, a PIEZOSTAT limits the pressure to the needed set valve and, in the event of its failure; a spring-loaded safety valve releases the steam to keep pressure within the safety limits.

- A spring-loaded safety valve and a dead weight release valve are installed at the chamber level to release steam if the pressure exceeds the safety limit. All of these safety features work independently of one another in the event of a failure.

- The discharge pipe is protected against choking by a plug screen. The plug may be readily removed for cleaning on a daily basis. The air is circulated throughout the chamber by a power ejector for drying sterilized lines. A corrosion-resistant metallic wool filter filters the circulating air. A steam trap is installed in the chamber discharge line to automatically remove the condensate.

- PID Controller operates fully automatically to display the chamber temperature.

- To break the vacuum created by steam condensation, an automatic vacuum breaker is provided.